China Prototype Manufacturing: Revolutionizing Metal Fabrication

In today's rapidly evolving industrial landscape, China prototype manufacturing has emerged as a pivotal player, especially in the field of metal fabrication. Businesses across the globe are increasingly looking to China as a manufacturing hub, attracted by its innovative techniques, cost-effectiveness, and advanced technology. This article delves into the myriad benefits and processes of prototype manufacturing in China, illustrating how it is reshaping the future of business and manufacturing.

Understanding China Prototype Manufacturing

Prototype manufacturing in China encompasses the rapid development of prototypes for various materials, particularly metals. This process includes designing, creating, and testing a model of a product before full-scale production. By employing advanced technologies and skilled labor, Chinese manufacturers can produce high-quality prototypes with impressive speed and accuracy.

The Importance of Prototyping

Before delving deeper into China prototype manufacturing, it's essential to understand why prototyping is crucial in many industries:

- Validation of Design: Prototypes allow businesses to test and validate designs, ensuring they meet technical and functional requirements.

- Cost Efficiency: By identifying flaws early in the process, companies can avoid costly rework and adjustments during mass production.

- Market Testing: Prototypes enable companies to gather user feedback and insights, which can be invaluable for refining product features.

- Time Savings: Rapid prototyping accelerates the development process, allowing companies to bring products to market faster.

Main Types of Prototyping in China

China excels in various types of prototyping, each offering unique advantages. The primary categories include:

1. 3D Printing Prototyping

3D printing technology has revolutionized prototype manufacturing by allowing for quick and cost-effective model creation. It enables the testing of intricate designs that would otherwise be difficult to manufacture using traditional methods.

2. CNC Machining Prototyping

Computer Numerical Control (CNC) machining is another flagship method in China prototype manufacturing. This technique employs precision machinery to carve out parts from solid blocks of materials, achieving high levels of detail and accuracy.

3. Injection Molding Prototyping

Injection molding is typically used for mass production but is also valuable during the prototyping phase. This method involves creating a mold and injecting materials to produce a product, making it optimal for producing parts with complex shapes.

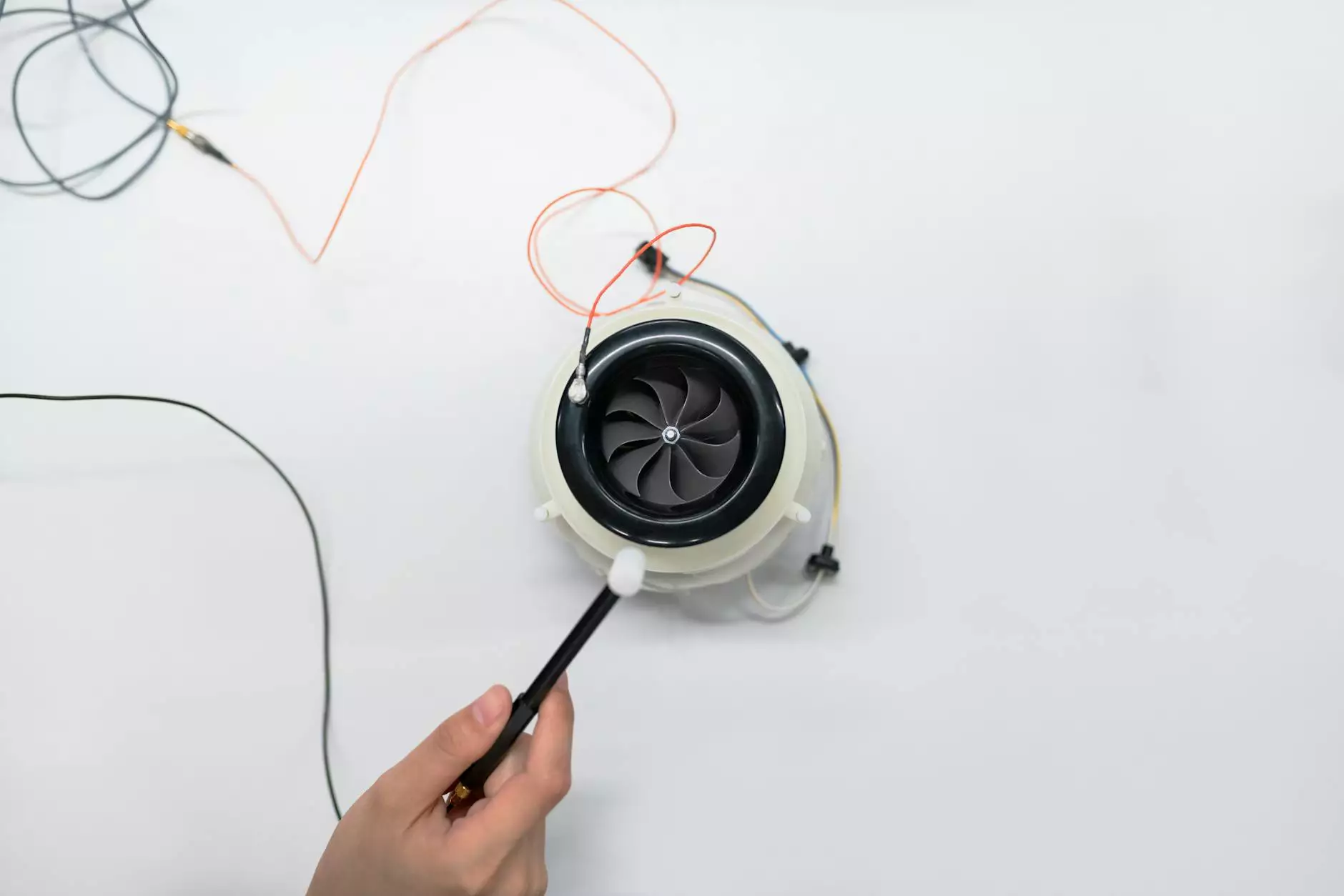

4. Sheet Metal Prototyping

Metal prototyping is crucial for industries that require strong, durable products. Chinese manufacturers leverage advanced metalworking technologies to produce prototypes from various metals.

Benefits of China Prototype Manufacturing

With a keen focus on innovation and efficiency, China prototype manufacturing offers numerous benefits that appeal to global businesses:

- Cost-Effectiveness: Lower labor and material costs in China facilitate economic prototype manufacturing, providing significant savings for companies.

- Speed to Market: Rapid prototyping processes minimize lead time, enabling faster transitions from concept to final product.

- Advanced Technology: China is at the forefront of manufacturing technologies, utilizing state-of-the-art equipment and skilled labor to produce high-quality prototypes.

- Wide Range of Materials: Chinese manufacturers can cater to diverse material needs, including various metals, plastics, and composites.

The Role of Deep Mould in China Prototype Manufacturing

As a leading provider in this arena, Deep Mould stands out for its commitment to excellence in metal fabrication and prototype manufacturing. The company specializes in:

- Precision Engineering: Using advanced CNC machining and 3D printing technology to create precise metal prototypes.

- Custom Solutions: Working closely with clients to develop tailored prototypes that fit their unique requirements.

- Quality Assurance: Implementing rigorous testing and quality control processes to ensure all prototypes meet industry standards.

The Prototype Manufacturing Process in China

The journey of prototype manufacturing in China typically involves several key stages:

1. Initial Consultation

Collaborating with clients to gather requirements, specifications, and expectations for the prototype is the first step. This stage lays the groundwork for the entire manufacturing process.

2. Design Development

Engineers and designers create blueprints and digital models using specialized CAD software. Prototyping technologies such as 3D printing and CNC machining allow for rapid iteration.

3. Prototype Creation

Once the design is finalized, manufacturing begins. Depending on the chosen method, materials are procured, and prototypes are built using either additive or subtractive manufacturing technologies.

4. Testing and Iteration

Prototypes undergo rigorous testing to identify any flaws or improvements. Feedback is incorporated, and designs may be refined for optimization.

5. Final Approval and Production

Upon successful testing and approval from the client, the prototype can move into full-scale production, leveraging the efficiencies gained during the prototyping phase.

Challenges in China Prototype Manufacturing

While the advantages of China prototype manufacturing are significant, it is essential also to recognize and address potential challenges:

- Quality Control: Ensuring consistent quality across multiple prototypes can be challenging, thus necessitating diligent oversight.

- Communication Barriers: Language differences may pose difficulties in conveying requirements between clients and manufacturers.

- Intellectual Property Concerns: Protecting designs and innovations is crucial, especially when working with overseas partners.

Future Trends in China Prototype Manufacturing

The landscape of prototype manufacturing is continually evolving, and several trends are poised to shape the future:

1. Automation and AI Integration

The adoption of automation and artificial intelligence in manufacturing processes is on the rise. This technology enables better precision, faster production times, and cost reduction.

2. Sustainable Practices

As global awareness of environmental issues grows, manufacturers in China are increasingly adopting sustainable practices, including the use of eco-friendly materials and energy-efficient production methods.

3. Enhanced Collaboration Tools

With virtual collaboration technologies becoming more robust, it will be easier for businesses worldwide to work seamlessly with Chinese manufacturers, enhancing communication and oversight.

Conclusion

In conclusion, China prototype manufacturing offers a wealth of opportunities for businesses seeking to innovate and optimize their manufacturing processes. With a unique blend of advanced technology, cost efficiency, and rapid production capabilities, China stands at the forefront of the global manufacturing industry. Companies like Deep Mould exemplify the potential of partnering with Chinese manufacturers for high-quality prototyping solutions. By leveraging these capabilities, businesses can accelerate their product development cycles while maintaining the highest standards of quality and precision.

As industries continue to evolve, embracing the benefits of China’s prototype manufacturing will undoubtedly play a critical role in shaping the future of global business.