Mastering the Art of Manufacturing Models in Architecture

Manufacturing models play a crucial role in the field of architecture, offering a robust way to visualize spatial concepts and designs before the actual construction begins. This article will delve into various aspects of manufacturing models, including their types, importance, and the technological innovations shaping the future of architectural modeling. Whether you're an architect, a student, or someone interested in the architectural field, understanding the significance of these models is essential.

The Importance of Manufacturing Models in Architecture

In the world of architecture, a stark understanding of design through physical representation is fundamental. Here are several key reasons why manufacturing models matter:

- Enhanced Visualization: Manufacturing models help clients visualize complex designs in ways that drawings or digital presentations may not fully capture.

- Effective Communication: These models serve as a communication tool between architects, clients, and builders, ensuring everyone is on the same page.

- Design Validation: Before construction, architects can assess the practicality of their designs, allowing for adjustments and refinements based on real-world spatial relationships.

- Marketing Advantages: High-quality physical models can be a powerful tool in promoting architectural projects, giving prospective clients and investors a tangible preview of what to expect.

- Educational Purposes: Models are invaluable in architectural education, enabling students to grasp intricate design concepts and principles through hands-on experience.

Types of Manufacturing Models

There are several types of manufacturing models used in architecture, each serving different purposes and needs. Here's an overview of the most common types:

1. Conceptual Models

Conceptual models are *simple representations* that convey the general idea of a design. They are often created early in the design process, focusing on massing and spatial relationships rather than detailed elements.

2. Presentation Models

These models are crafted for presentation to clients or stakeholders. They incorporate intricate details and high-quality finishes, showcasing the architect's vision effectively.

3. Working Models

Working models are built to explore design alternatives and work through structural engineering considerations. They are typically more functional and may include movable parts to explain certain features.

4. Scale Models

Scale models represent buildings at a reduced size. They are crucial for understanding the proportions and spatial dynamics within a context, allowing for better design evaluation.

5. Prototype Models

Prototype models test specific design elements or construction methods. They help in evaluating materials and techniques before full-scale production.

Materials Used in Manufacturing Models

The choice of materials in manufacturing models is critical, as they affect not only aesthetics but also functionality. Here are some commonly used materials:

- Balsa Wood: Light and easy to cut, making it ideal for creating complex shapes and forms.

- Foam Core: It provides a smooth surface for paint and markers, commonly used in presentation models.

- Cardboard: An inexpensive and readily available material suitable for building quick models.

- 3D Printing Materials: Advanced technologies allow architects to create highly detailed and accurate models using various materials like PLA or resin.

- Plastic: Often used for commercial models, providing durability and a polished look.

Technological Innovations in Model Manufacturing

Technological advancements have substantially changed how manufacturing models are created. Here are some key innovations:

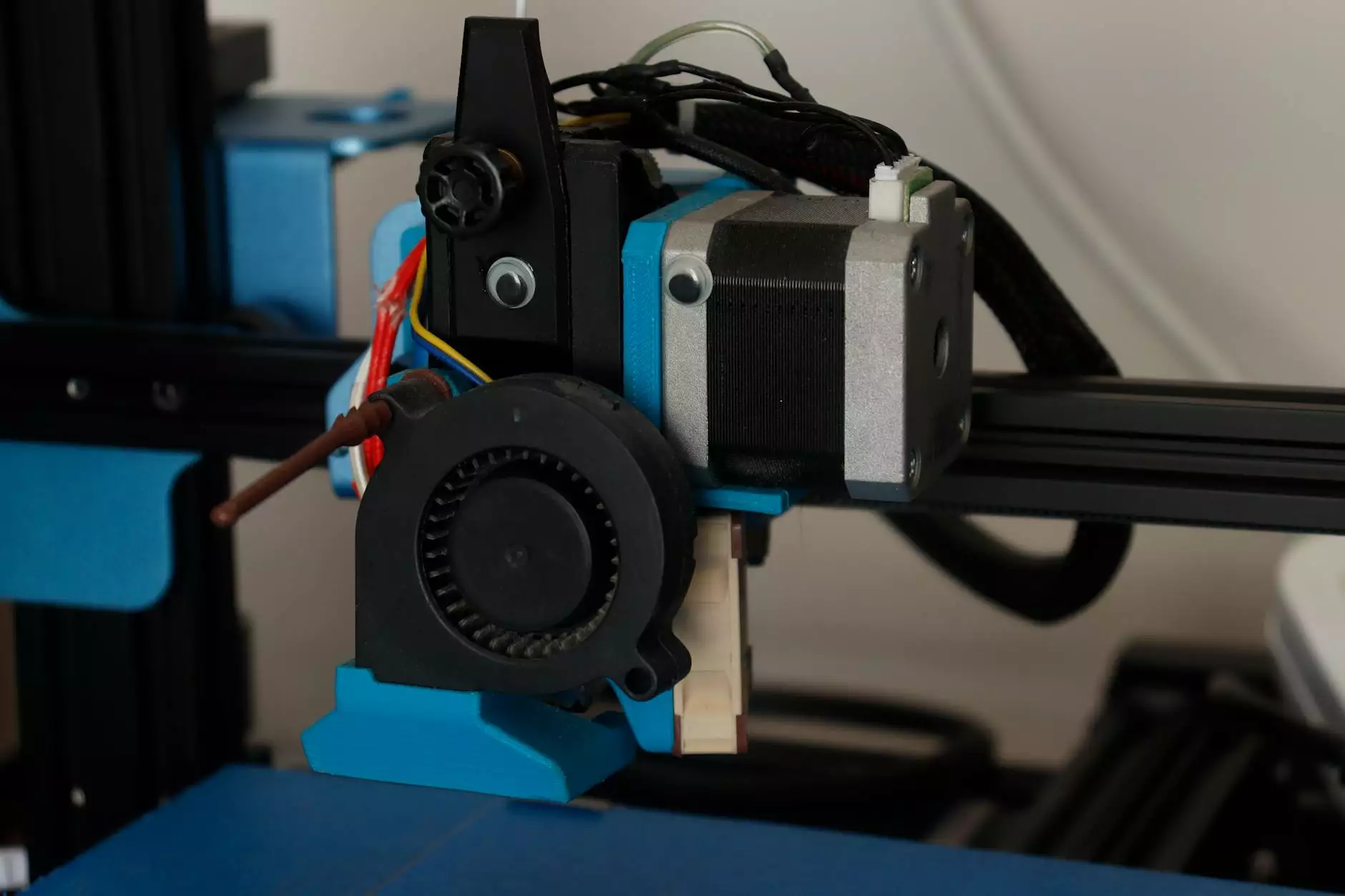

1. 3D Printing

3D printing technology has revolutionized how models are manufactured. Architects can produce highly detailed, intricate designs that were previously not feasible with conventional modeling techniques. This process allows for rapid prototyping, where multiple iterations can be tested quickly and efficiently.

2. Virtual Reality (VR)

Virtual reality has introduced immersive environments where architects can walk clients through their designs. Combining physical models with VR provides an unprecedented understanding of spatial dynamics.

3. Computer-Aided Design (CAD)

CAD software enables architects to create detailed digital models that can directly inform the manufacturing process. This integration improves accuracy and efficiency, serving as a foundation for both digital and physical models.

4. Laser Cutting and CNC Machining

These technologies allow for precise cuts and engravings in various materials. They are particularly useful for creating complex geometries that are otherwise challenging to achieve manually.

The Process of Manufacturing Models

Creating an effective manufacturing model involves several steps:

- Concept Development: Begin with ideation sessions to brainstorm around the design and functionality of the model.

- Material Selection: Choose the appropriate materials based on the model’s purpose (i.e., presentation, working, or prototype).

- Design and Creation: Using CAD software, finalize the design before beginning physical construction.

- Assembly: Cut, shape, and construct the model using your chosen materials.

- Finishing Touches: Paint, add textures, and make adjustments to enhance visual appeal and realism.

Challenges in Manufacturing Models

Despite their advantages, the process of manufacturing models can be fraught with challenges:

- Time Constraints: Balancing project timelines with model manufacturing can be tricky, as detailed models require significant time investment.

- Budget Limitations: High-quality models often come with a high price tag, which might exceed project budgets.

- Material Limitations: Choosing the right material that fits both functionality and aesthetics can pose challenges, especially with varying costs and properties.

- Technological Hurdles: Not all firms have access to the latest technologies or expertise, making some innovations difficult to implement.

The Future of Manufacturing Models in Architecture

The future of manufacturing models in architecture looks promising, driven by continual technological advancements and a growing emphasis on sustainability. Here are some key trends to watch:

1. Sustainability in Modeling

As environmental concerns become increasingly important, architects are seeking sustainable materials and practices in model manufacturing. This shift encompasses the use of recycled materials, biodegradable options, and methods that reduce waste.

2. Increased Use of Automation

Automation in model manufacturing is likely to rise. Automated tools and robotics can enhance precision and efficiency in creating models, making the process faster and more cost-effective.

3. Greater Integration of Digital and Physical Models

Architects will continue to blend digital tools with physical modeling. This hybrid approach will allow for more dynamic presentations and facilitate better decision-making processes.

Conclusion

In the realm of architecture, manufacturing models are indispensable. They bridge the gap between vision and reality, transforming abstract ideas into tangible forms that can be communicated effectively. As technology evolves, so too will the methods and materials architects employ in creating these models, paving the way for creativity, innovation, and enhanced communication in the architectural process. Embracing advancements in model manufacturing not only benefits architects but also enriches the client experience, ensuring that every project is well-prepared for a successful execution.